WMoTaNb Alloy Powder (Tungsten Molybdenum Tantalum Niobium)

AvailableTungsten Molybdenum Tantalum Niobium Alloy Powder for 3D PrintingTungsten Molybdenum Tantalum Niobium Alloy Powder for AMWholesale & RetailManufacturer & Supplier

Symbol: WMoTaNbComposition: As requiredParticle size: 15-45 um, 15-53 um, 45-105 um, etc.Shape: SphericalIn Stock: AvailableShips to: Worldwide

Tungsten Molybdenum Tantalum Niobium Alloy Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| WMoTaNb-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| WMoTaNb-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| WMoTaNb-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| WMoTaNb-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

Tungsten Molybdenum Tantalum Niobium Alloy Powder

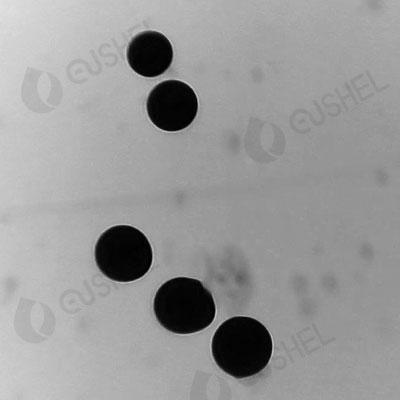

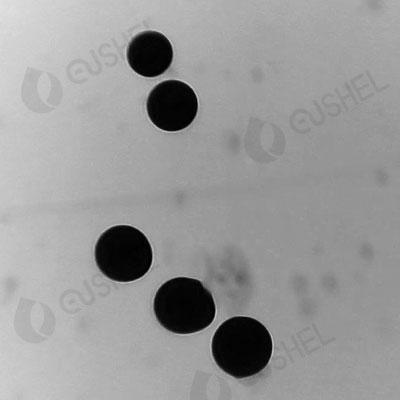

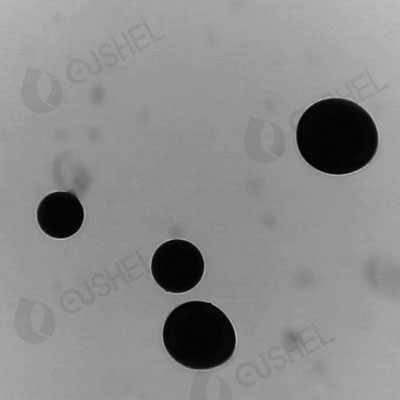

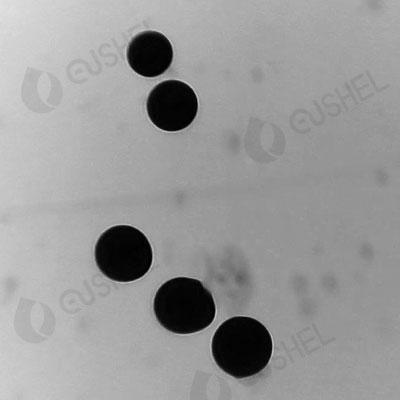

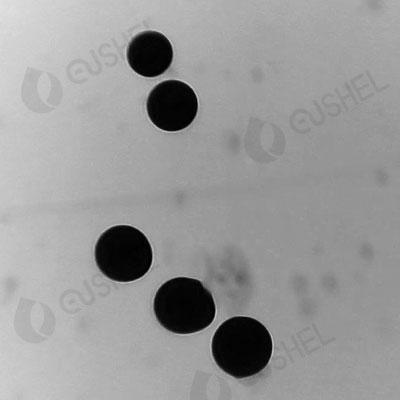

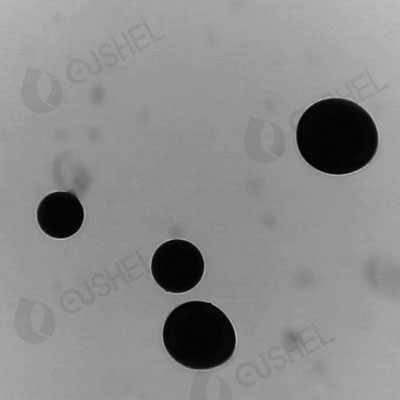

Tungsten molybdenum tantalum niobium alloy powder refers to the process of melting high-purity

tungsten powder,

molybdenum powder,

tantalum powder, and

niobium powder into tungsten molybdenum tantalum niobium alloy ingots in a certain proportion, crushing the ingots into tungsten molybdenum tantalum niobium alloy particles, and then producing spherical tungsten molybdenum tantalum niobium alloy powder through plasma spheroidization technology. Finally, the tungsten molybdenum tantalum niobium alloy powder are obtained through screening.

In addition, tungsten molybdenum tantalum niobium alloy powder can also be produced by plasma rotating electrode technology, where tungsten powder, molybdenum powder, tantalum powder, and niobium powder are melted in a certain proportion in advance to form tungsten molybdenum tantalum niobium alloy rods, and then processed into tungsten molybdenum tantalum niobium alloy powder through plasma rotating electrode technology. Considering the factors of economic cost and particle size, plasma spheroidization process is commonly used to produce spherical tungsten molybdenum tantalum niobium alloy powder.

Tungsten Molybdenum Tantalum Niobium Alloy Powder Application

Tungsten molybdenum tantalum niobium alloy powder is not a common powder. It is mainly customized according to customer's requirements. We mainly produce spherical tungsten molybdenum tantalum niobium alloy powders of various particle sizes through plasma spheroidization process. It can be used in the following situations:

1. Tungsten molybdenum tantalum niobium alloy powder is mainly used in 3D printing / additive manufacturing;

2. Tungsten molybdenum tantalum niobium alloy powder can also be used for thermal spraying, laser cladding, injection molding and other occasions.

| Spec. |

Shape |

Particle Size |

Application |

| WMoTaNb-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| WMoTaNb-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| WMoTaNb-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| WMoTaNb-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products

https://www.fusnano.com/am/spherical-molybdenum-powder.htmlSpherical molybdenum powder is the molybdenum powder which is spherical under scanning electron microscope (SEM). Spherical molybdenum powder is generally produced by plasma spheroidization or plasma rotating electrode equipment.

https://www.fusnano.com/am/spherical-tantalum-powder.htmlSpherical tantalum powder is tantalum powder which is spherical under scanning electron microscope (SEM). Compared with irregular tantalum powder, the production cost of spherical tantalum powder is higher. It is mainly produced by plasma rotating electrode method and induction plasma spheroidization process.

https://www.fusnano.com/metal/niobium-powder.htmlThe spherical niobium powder produced by FUSHEL is produced by plasma spheroidization technology, which has the advantages of high sphericity and narrow particle size distribution. It is mainly used in 3D printing/additive manufacturing, thermal spraying, laser cladding, injection molding and other occasions.