M2 High Speed Steel Powder

AvailableM2 High Speed Steel Powder for 3D PrintingM2 High Speed Steel Powder for AMWholesale & RetailManufacturer & Supplier

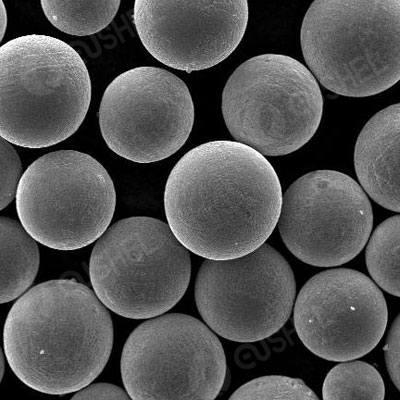

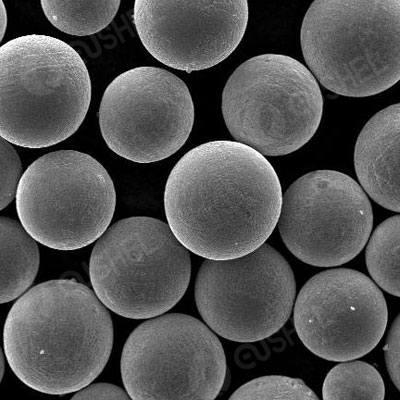

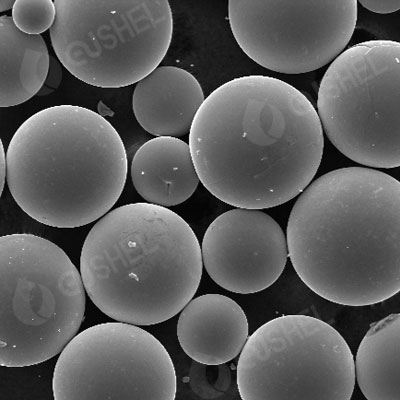

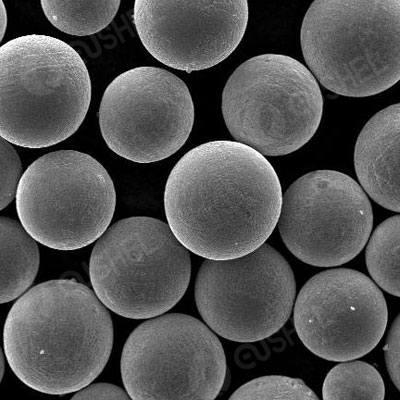

Symbol: M2Composition: W 5.5-6.75%, Mo 4.5-5.5%, Cr 3.8-4.4%, V 1.75-2.2%Particle size: 15-45 um, 15-53 um, 45-105 um, etc.Shape: SphericalIn Stock: AvailableShips to: Worldwide

M2 High Speed Steel Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| M2-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| M2-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| M2-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| M2-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

M2 High Speed Steel Powder

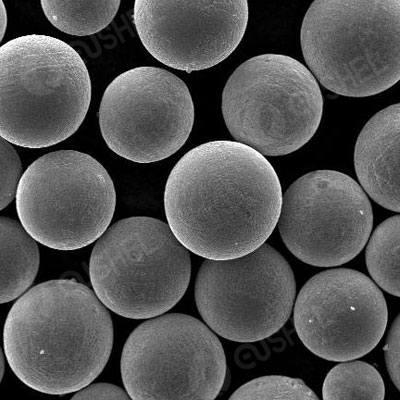

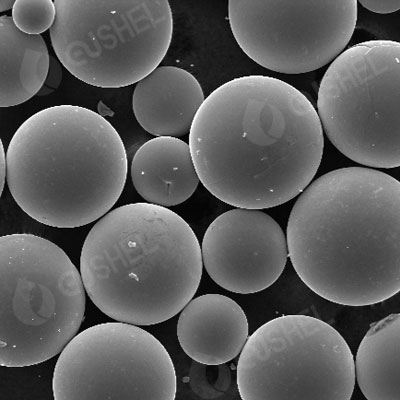

M2 high speed steel powder is an iron-based alloy powder with iron as the main element and a small amount of refractory metal elements such as chromium, tungsten, molybdenum and vanadium. M2 high speed steel has the advantages of low carbide heterogeneity and high toughness. It is easy to overheat and has good hardness and wear resistance. It is mostly used to manufacture cutting tools for cutting difficult materials.

Preparation Process of M2 High Speed Steel Powder

① Using high-purity

chromium powder,

vanadium powder,

tungsten powder,

molybdenum powder, iron powder etc. melted into M2 alloy steel according to the standard composition ratio of M2 alloy steel;

② Producing spherical

M2 alloy steel powder through gas atomization process;

③ Screening and vacuum packaging.

Chemical Composition of M2 High Speed Steel Powder

| Cr |

Mo |

V |

Mn |

Fe |

W |

Si |

| 3.8-4.4% |

4.5-5.5% |

1.75-2.2% |

0.2-0.45% |

Balance |

5.5-6.75% |

0.15~0.40% |

| Ni |

C |

S |

P |

O |

|

|

| ≤ 0.30% |

0.80~0.90% |

≤ 0.03% |

≤ 0.03% |

≤ 0.08% |

|

|

M2 High Speed Steel Powder Application

The M2 high speed steel powder produced by FUSHEL has the characteristics of high batch stability, good sphericity, low oxygen content, uniform particle size distribution, good fluidity, high loose density and vibrated density. The powder can be used in laser / electron beam additive manufacturing (SLM / EBM), powder metallurgy (PM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM) and other processes. It is mainly used in 3D printing thin-walled devices and complex parts, cold and hot spraying, laser cladding and biomedical fields.

| Spec. |

Shape |

Particle Size |

Application |

| M2-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| M2-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| M2-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| M2-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products

https://www.fusnano.com/am/h13-tool-steel-powder.htmlH13 tool steel powder is an iron-based alloy powder with iron as the main component, chromium content of 4.75-5.50%, molybdenum content of 1.10-1.75% and vanadium content of 0.80-1.20%.

https://www.fusnano.com/am/m300-tool-steel-powder.htmlM300 tool steel powder is a kind of ultra-high strength steel powder with carbon free or micro carbon martensite as matrix, which precipitates alloy compounds during aging through alloy elements such as Mo, Co, Ti and Al to form the second phase strengthening.