Inconel 738LC Alloy Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| IN738LC-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| IN738LC-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| IN738LC-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| IN738LC-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

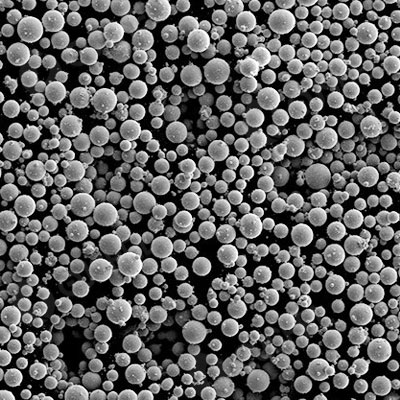

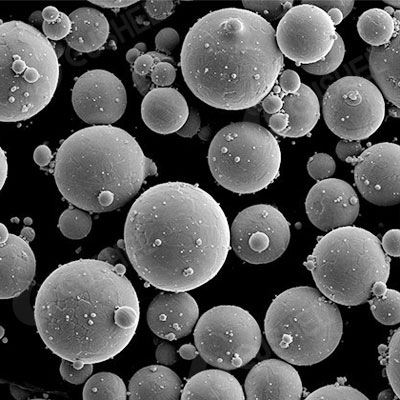

Inconel 738LC Alloy Powder

IN738 alloy is a precipitation strengthened nickel based high-temperature alloy containing insoluble elements such as Mo, W, Ta, Nb, etc. This alloy exhibits high resistance to oxidation, corrosion, and creep due to the combined effects of solid solution strengthening by Mo, W, and Cr dissolved in the matrix, precipitation strengthening by intermetallic compounds, and grain boundary strengthening by metal carbides. Therefore, it has been widely used in the manufacturing of heat-resistant and corrosion-resistant turbine components in the petrochemical and aerospace industries for a long time. According to the different carbon contents, IN738 has two improved alloys, one is the low-carbon

IN738LC alloy, and the other is the ultra-low carbon IN738FC alloy.

IN738LC is a typical γ-phase precipitation strengthened nickel based high-temperature alloy. It has excellent high-temperature durability and good corrosion and fatigue resistance, and is widely used in hot end components such as ships, industrial gas turbines, and aircraft engines operating at temperatures below 900 ℃.

IN738LC Alloy Powder Preparation Process

① Using high-purity

nickel powder,

chromium powder,

cobalt powder, titanium powder, aluminum powder,

molybdenum powder,

tungsten powder,

tantalum powder,

niobium powder and other raw materials in a certain proportion to prepare IN738LC master alloy;

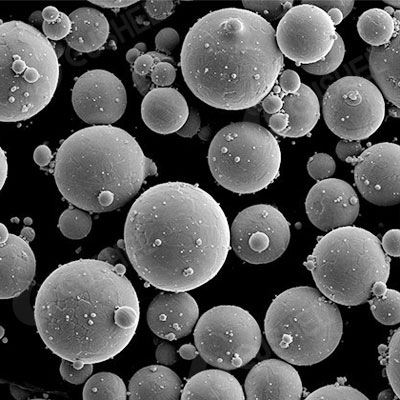

② Using gas atomization technology to produce spherical

IN738LC powder from IN738LC master alloy;

③ Screening and vacuum packaging.

Chemical Composition of Inconel 738LC Alloy Powder

| Cr |

Co |

Ti |

Al |

Mo |

W |

Ni |

| 14.0-16.0% |

8.0-9.0% |

2.5-4.0% |

2.5-4.0% |

1.0-2.0% |

2.0-3.0% |

Balance |

| Ta |

Nb |

C |

Fe |

Zr |

B |

O |

| 1.0-2.0% |

0.5-1.5% |

≤0.15% |

≤0.1% |

≤0.1% |

≤0.15% |

≤0.01% |

Inconel 738LC Alloy Powder Application

IN738LC alloy is a typical γ-phase precipitation strengthened nickel based high-temperature alloy, which has excellent high-temperature durability, good corrosion resistance, fatigue resistance and other characteristics. It is widely used in hot end components such as ships, industrial gas turbines and aviation engines below 900 ℃ working temperature.

The IN738LC alloy powder produced by FUSHEL has the characteristics of high batch stability, good sphericity, low oxygen content, uniform particle size distribution, good fluidity, high loose density and vibrated density. The powder can be used in laser / electron beam additive manufacturing (SLM / EBM), powder metallurgy (PM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM) and other processes. It is mainly used to make working blades and guide blades of gas turbine and aeroengine turbine.

| Spec. |

Shape |

Particle Size |

Application |

| IN738LC-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| IN738LC-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| IN738LC-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| IN738LC-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products

CM247LC alloy powder is a kind of low-carbon nickel based alloy powder with nickel as the main component and adding metal elements such as cobalt, chromium, tungsten, tantalum, aluminum and hafnium.

https://www.fusnano.com/am/cm247lc-nickel-alloy-powder.html

Inconel 939 nickel alloy powder is a precipitation hardening cast superalloy, which has high creep strength, cold and hot fatigue resistance and oxidation resistance.

https://www.fusnano.com/am/in939-nickel-alloy-powder.html

Inconel 713 nickel alloy powder is a precipitation hardening cast superalloy, which has high creep strength, cold and hot fatigue resistance and oxidation resistance.

https://www.fusnano.com/am/in713-nickel-alloy-powder.html

Inconel 718 alloy powder is a precipitation hardening nickel chromium iron alloy powder containing niobium and molybdenum.

https://www.fusnano.com/am/in718-nickel-alloy-powder.html

Inconel 625 alloy powder is a kind of nickel based alloy powder with nickel as the main component and chromium, molybdenum, niobium, iron, cobalt and other elements added.

https://www.fusnano.com/am/in625-nickel-alloy-powder.html

Nickel titanium alloy powder refers to a binary alloy powder made of nickel and titanium in different proportions.

https://www.fusnano.com/am/niti50-nickel-titanium-alloy-powder.html