Inconel 625 Alloy Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| IN625-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| IN625-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| IN625-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| IN625-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

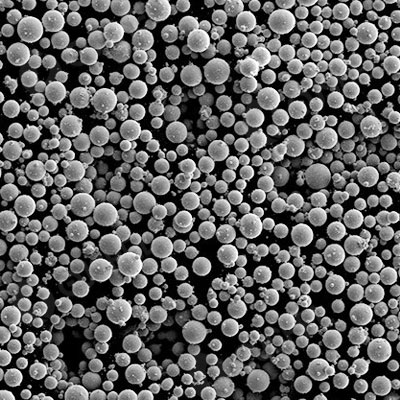

Inconel 625 Alloy Powder

Inconel 625 is a kind of nickel based alloy with nickel as the main component and chromium, molybdenum, niobium, iron, cobalt and other elements added.

Inconel 625 alloy has excellent inorganic acid corrosion resistance and excellent corrosion resistance to various corrosive media in oxidation and reduction environment. Inconel 625 is also a solid solution strengthened nickel based high-temperature alloy with excellent corrosion resistance, oxidation resistance, and mechanical properties, suitable for the aerospace and chemical industries.

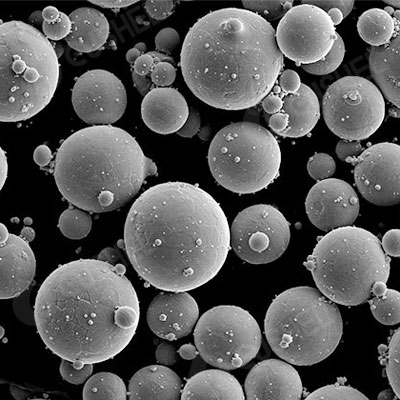

Preparation Process of Inconel 625 Alloy Powder

① Using high-purity

nickel powder,

chromium powder,

molybdenum powder,

niobium powder and other raw materials in a certain proportion to make IN625 master alloy;

② Producing spherical

IN625 powder from IN625 master alloy through gas atomization process;

③ Screening and vacuum packaging.

Chemical Composition of Inconel 625 Nickel Alloy Powder

| C |

Si |

Mn |

Ni |

Cr |

Co |

Mo |

| ≤0.1% |

≤0.5% |

≤0.5% |

Balance |

20-23.0% |

≤1.1% |

8.0-10.0% |

| Al |

Cu |

Ti |

Nb |

P |

S |

Fe |

| ≤0.4% |

≤0.07% |

≤0.4% |

3.15-4.15% |

≤0.015% |

≤0.015% |

≤5.0% |

Inconel 625 Alloy Powder Application

Inconel 625 alloy is a solid solution strengthened nickel based high-temperature alloy with excellent corrosion resistance, oxidation resistance, and mechanical properties, suitable for the aerospace and chemical industries. The details are as follows:

1. Aircraft engine parts: Inconel 625 alloy can be applied to key components of aircraft engines, such as turbine blades, combustion chambers, etc.

2. Aerospace structural components: Inconel 625 alloy is an ideal material for manufacturing aerospace structural components due to its high strength, good toughness, and excellent corrosion resistance.

3. Chemical equipment: Inconel 625 alloy not only maintains good performance in corrosive media such as acid and alkali, but also resists the erosion of chloride ions, thus it has been widely used in the field of chemical equipment manufacturing.

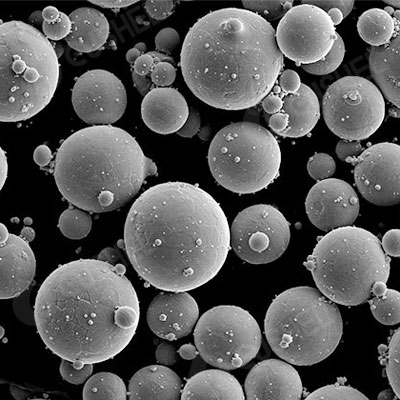

The IN625 alloy powder produced by FUSHEL has the characteristics of high batch stability, good sphericity, low oxygen content, uniform particle size distribution, good fluidity, high loose density and vibrated density. The powder can be used in laser / electron beam additive manufacturing (SLM / EBM), powder metallurgy (PM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM) and other processes. It is widely used in industrial and aviation steam turbine, petrochemical industry, nuclear reactor, laser cladding and other fields.

| Spec. |

Shape |

Particle Size |

Application |

| IN625-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| IN625-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| IN625-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| IN625-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products

CM247LC alloy powder is a kind of low-carbon nickel based alloy powder with nickel as the main component and adding metal elements such as cobalt, chromium, tungsten, tantalum, aluminum and hafnium.

https://www.fusnano.com/am/cm247lc-nickel-alloy-powder.html

Inconel 939 nickel alloy powder is a precipitation hardening cast superalloy, which has high creep strength, cold and hot fatigue resistance and oxidation resistance.

https://www.fusnano.com/am/in939-nickel-alloy-powder.html

Inconel 713 nickel alloy powder is a precipitation hardening cast superalloy, which has high creep strength, cold and hot fatigue resistance and oxidation resistance.

https://www.fusnano.com/am/in713-nickel-alloy-powder.html

Inconel IN738LC alloy powder is a precipitation hardening nickel chromium cobalt alloy powder with titanium, aluminum, molybdenum, tungsten.

https://www.fusnano.com/am/in738lc-nickel-alloy-powder.html

Inconel 718 alloy powder is a precipitation hardening nickel chromium iron alloy powder containing niobium and molybdenum.

https://www.fusnano.com/am/in718-nickel-alloy-powder.html

Nickel titanium alloy powder refers to a binary alloy powder made of nickel and titanium in different proportions.

https://www.fusnano.com/am/niti50-nickel-titanium-alloy-powder.html