CoCrNiW Alloy Powder (Cobalt Chromium Nickel Tungsten)

AvailableCoCrNiW Alloy Powder for 3D PrintingCoCrNiW Alloy Powder for AMWholesale & RetailManufacturer & Supplier

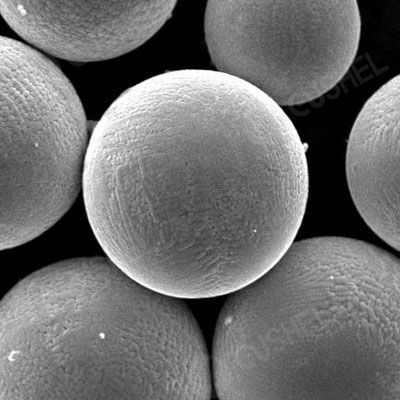

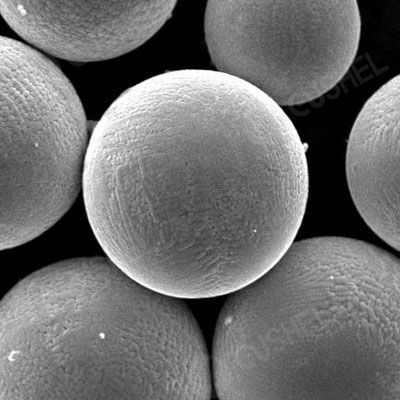

Symbol: CoCrNiWComposition: Cr 19-24%, Ni 9-24%%, W 13-16%, Co balanceParticle size: 15-45 um, 15-53 um, 45-105 um, etc.Shape: SphericalIn Stock: AvailableShips to: Worldwide

CoCrNiW Alloy Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| CoCrNiW-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| CoCrNiW-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| CoCrNiW-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| CoCrNiW-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

CoCrNiW Alloy Powder

Cobalt chromium nickel tungsten alloy (

CoCrNiW) is a kind of cobalt based alloy with cobalt as the main component and a small amount of chromium, nickel, tungsten, iron and other elements. It can be used in aerospace, automobile, biomedicine, electronic product welding, powder metallurgy parts and other fields.

Preparation Process of CoCrNiW Alloy Powder

① Smelt high-purity

cobalt powder,

chromium powder,

nickel powder and

tungsten powder into cobalt chromium nickel tungsten master alloy in a certain proportion;

② Producing spherical

CoCrNiW powder through gas atomization process;

③ Screen screening and vacuum packaging.

Chemical Composition of CoCrNiW Alloy Powder

| Spec. |

Cr |

Ni |

W |

Fe |

Co |

| CoCrNiW-1 |

20.0-24.0% |

20.0-24.0% |

13.0-16.0% |

≤3.0% |

Balance |

| CoCrNiW-2 |

19.0-21.0% |

9.0-11.0% |

14.0-16.0% |

≤3.0% |

Balance |

CoCrNiW Alloy Powder Application

The CoCrNiW alloy powder produced by FUSHEL has the characteristics of high batch stability, good sphericity, low oxygen content, uniform particle size distribution, good fluidity, high loose density and vibrated density. It is mainly used in laser / electron beam additive manufacturing (SLM / EBM), powder metallurgy (PM), laser cladding, laser direct deposition (DLD), powder hot isostatic pressing (hip), metal injection molding (MIM) and other processes. It can be used in aerospace, automobile, biomedicine, electronic product welding, powder metallurgy parts and other fields.

| Spec. |

Shape |

Particle Size |

Application |

| CoCrNiW-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| CoCrNiW-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| CoCrNiW-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| CoCrNiW-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products

https://www.fusnano.com/am/cobalt-chromium-tungsten-alloy-powder.htmlCobalt chromium tungsten alloy (

CoCrW) is a cobalt based alloy that can withstand various types of wear, corrosion, and high-temperature oxidation. It is a kind of cobalt based alloy with cobalt as the main component and a small amount of chromium, tungsten, silicon and other elements.

https://www.fusnano.com/am/cobalt-chromium-molybdenum-alloy-powder.htmlCobalt chromium molybdenum alloy (

CoCrMo) is a cobalt based alloy mainly composed of cobalt, chromium, and molybdenum. It has excellent mechanical properties and corrosion resistance.

https://www.fusnano.com/am/cobalt-chromium-molybdenum-tungsten-alloy-powder.htmlCobalt chromium molybdenum tungsten alloy (

CoCrMoW) is a cobalt based alloy mainly composed of cobalt, chromium, molybdenum, and tungsten in a certain proportion. CoCrMoW is a cobalt chromium alloy developed for use in medical fields such as orthopedic implants and dental restorations.

https://www.fusnano.com/am/cobalt-chromium-nickel-alloy-powder.htmlCobalt chromium nickel alloy (

CoCrNi) is a kind of cobalt based alloy with cobalt as the main component and a small amount of chromium, nickel, and other elements. It can be used in aerospace, automobile, biomedicine, electronic product welding, powder metallurgy parts and other fields.