7A04 Aluminum Alloy Powder

Dangerous goods, Not available7A04 Aluminum Alloy Powder for 3D Printing7A04 Aluminum Alloy Powder for AMWholesale & RetailManufacturer & Supplier

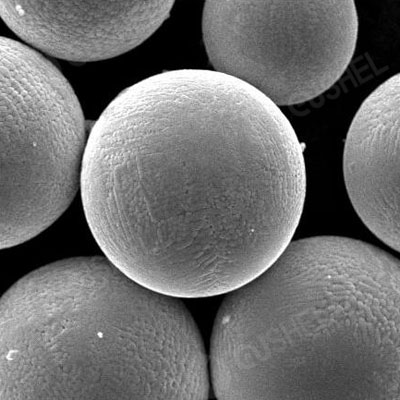

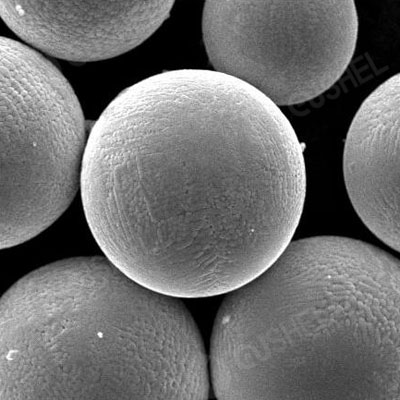

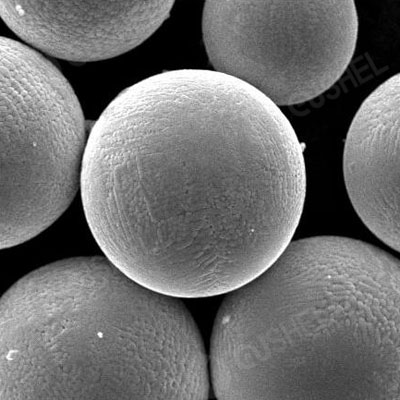

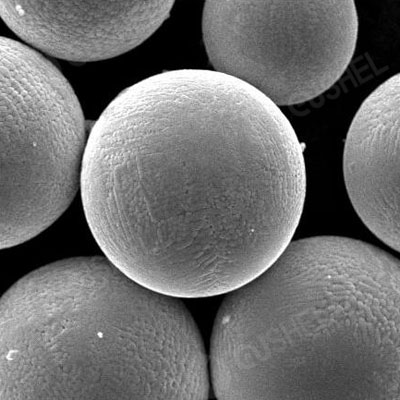

Symbol: 7A04Composition: Zn 5.0-7.0%, Mg 1.8-2.8%, Cu 1.4-2.0%, Al balanceParticle size: 15-45 um, 15-53 um, 45-105 um, etc.Shape: SphericalIn Stock: Dangerous goods, Not availableShips to: Worldwide

7A04 Aluminum Alloy Powder Price & List

| Spec. |

Shape |

Particle Size |

Application |

| 7A04-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| 7A04-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| 7A04-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| 7A04-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

7A04 Aluminum Alloy Powder

7A04 aluminum alloy powder is an aluminum based alloy powder with aluminum as the main component and added with 5.0-7.0% Zn, 1.8-2.8% Mg, 1.4-2.0% Cu, 0.2-0.6% Mn, 0.1-0.25% Cr and other metal elements. 7A04 aluminum alloy's strength is higher than that of hard aluminum. It is characterized by its yield strength close to tensile strength and plasticity, and its sensitivity to stress concentration is strong, especially when subjected to vibration load and repeated static load. It is widely used in aircraft structures, such as beams and stringers, bulkheads, ribs, skin, joints, undercarriage parts etc.. It can produce all kinds of semi-finished products, such as plate, strip, section, bar, wall, pipe, wire, free forgings and die forgings.

Chemical Composition of 7A04 Aluminum Alloy Powder

| Cu |

Mn |

Mg |

Cr |

Zn |

Al |

| 1.4-2.0% |

0.2-0.6% |

1.8-2.8% |

0.1-0.25% |

5.0-7.0% |

Balance |

| Si |

Fe |

Ti |

O |

|

|

| ≤ 0.5% |

≤ 0.5% |

≤ 0.1% |

< 0.05% |

|

|

7A04 Aluminum Alloy Powder Application

The 7A04 aluminum alloy powder produced by FUSHEL has the characteristics of high batch stability, good sphericity, low oxygen content, uniform particle size distribution, good fluidity, high loose density and vibrated density. It can be used in laser / electron beam additive manufacturing (SLM / EBM), powder metallurgy (PM), spraying and other processes. It is mainly used in the fields of aviation parts and auto parts, profile surface spraying and powder metallurgy.

| Spec. |

Shape |

Particle Size |

Application |

| 7A04-DS015045 |

Spherical |

15-45 um |

3D printing / additive manufacturing |

| 7A04-DS015053 |

Spherical |

15-53 um |

3D printing / additive manufacturing |

| 7A04-DS045105 |

Spherical |

45-105 um |

3D printing / additive manufacturing |

| 7A04-DS045150 |

Spherical |

45-150 um |

3D printing / additive manufacturing |

| Customizable |

Spherical |

Customizable |

3D printing / additive manufacturing |

Related Products